This article provides an in-depth overview of Mopp Tape, its characteristics, applications, and key considerations for selection. Discover how this versatile adhesive product can enhance productivity and efficiency in various industries.

Introduction to Mopp Tape

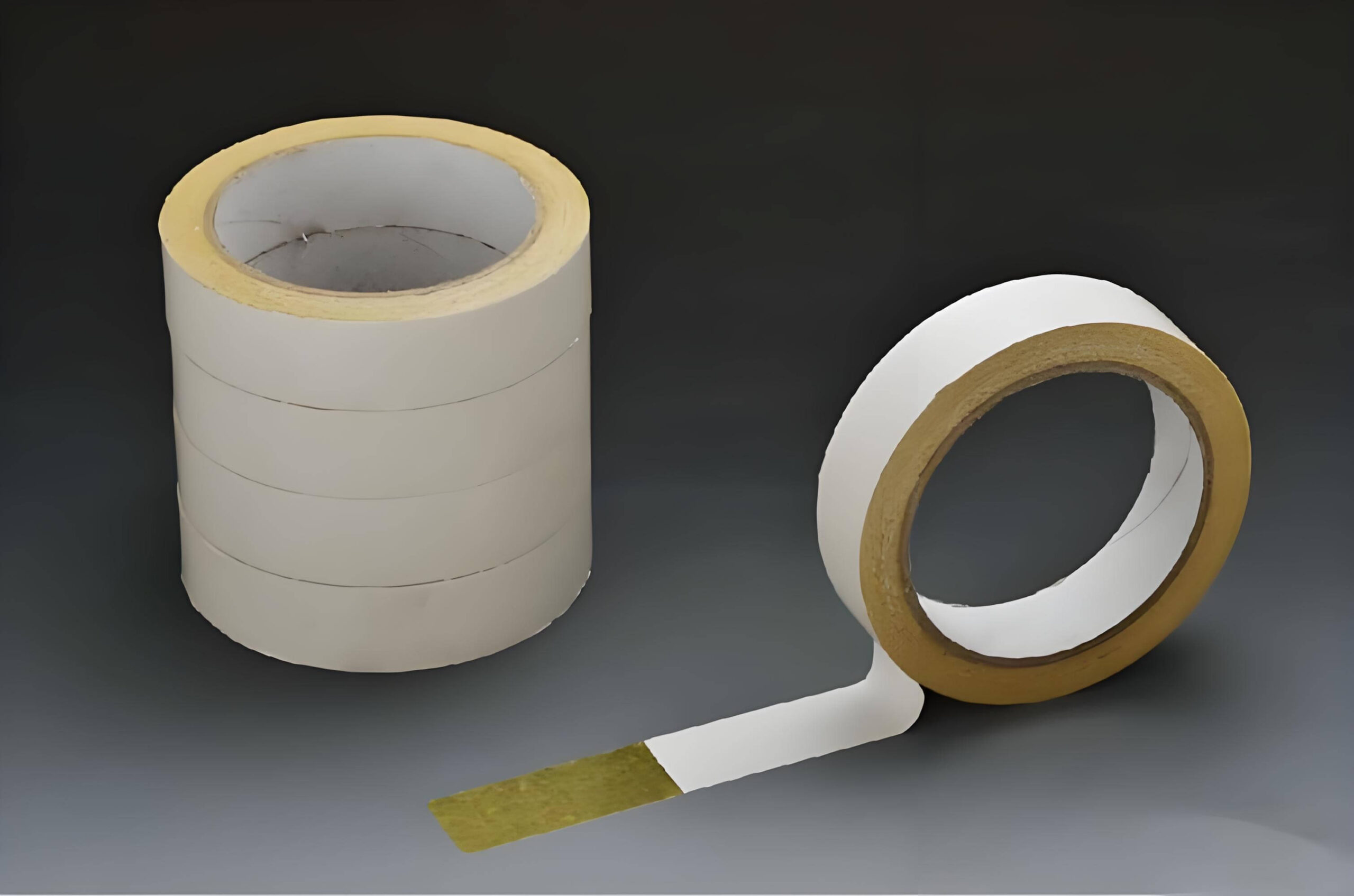

Mopp Tape, also known as Masking Tape or Painters Tape, is a pressure-sensitive adhesive tape used extensively in industrial settings. It is characterized by its strong adhesion, easy removal, and minimal residue left on surfaces. Mopp Tape is an essential tool for a wide range of applications, from painting and powder coating to manufacturing and automotive industries.

Characteristics of Mopp Tape

Strong Adhesion: Mopp Tape provides a secure bond on a variety of surfaces, including metal, plastic, and glass.

Easy Removal: Designed to be easily removed without leaving behind a sticky residue, making it ideal for temporary bonding applications.

Heat Resistance: Some types of Mopp Tape can withstand high temperatures, making them suitable for use in baking finishes or heat-sensitive environments.

UV Resistance: Specialized Mopp Tapes can resist UV light, preventing the tape from deteriorating when exposed to sunlight.

Applications of Mopp Tape

Automotive Industry: Used for masking off areas during painting and bodywork, ensuring clean and precise paint jobs.

Painting and Decorating: Ideal for protecting surfaces during painting, such as window frames, trim, and baseboards.

Powder Coating: Mopp Tape is used to mask off areas that should not be coated during the powder coating process.

Manufacturing: Utilized in assembly lines for temporary holding of parts during production.

Electronics: Used for insulating and protecting sensitive electronic components during manufacturing and repair.

Key Considerations for Selecting Mopp Tape

Adhesive Strength: Choose the appropriate strength based on the surface type and the duration of the bonding needed.

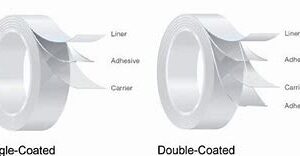

Material Type: Mopp Tape is available in various materials, such as paper, plastic, or fabric, each suitable for different applications.

Temperature Resistance: Consider the temperature range the tape will be exposed to, and select a product that can withstand those conditions.

Durability: Assess the wear and tear the tape will endure, including abrasion, moisture, and chemical exposure.

Removal: Ensure the tape can be removed without damaging the underlying surface or leaving behind adhesive residue.

Conclusion

Mopp Tape is a vital component in many industrial processes, offering a reliable and efficient bonding solution. By understanding its characteristics, applications, and selection criteria, businesses can make informed decisions to enhance their operations. Investing in high-quality Mopp Tape can lead to improved productivity, reduced waste, and a higher standard of finished products.